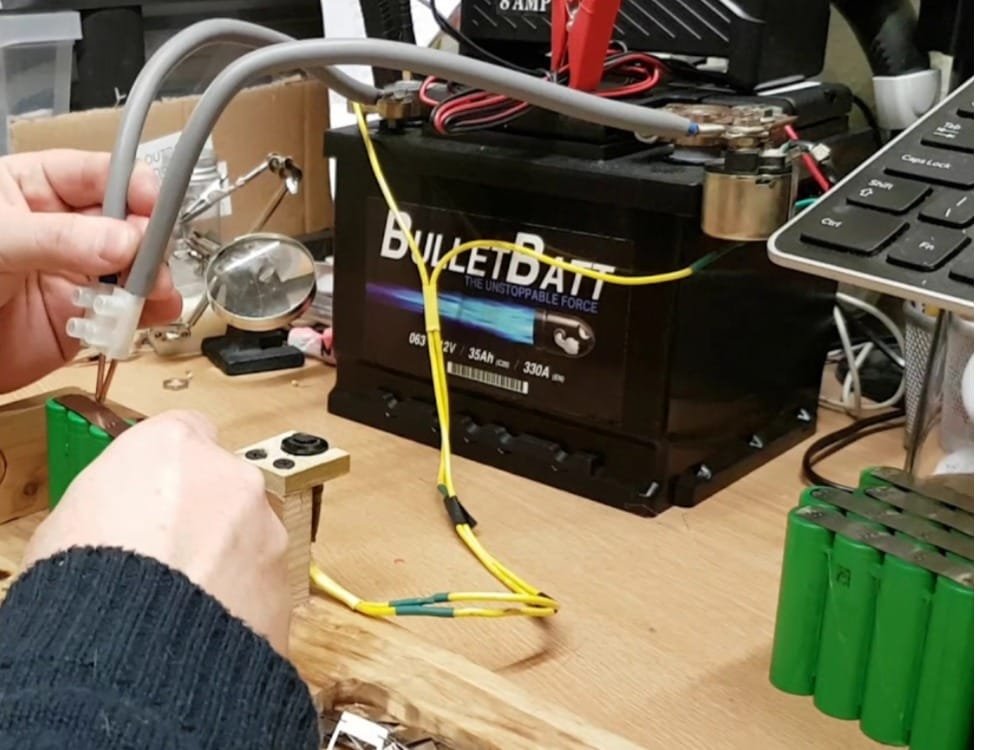

- Supports Continuous 20A+ High Discharge

- Available in 0.1–0.5mm Thickness / Custom Widths

- Precision Punching ±0.1mm – Custom Holes & Lengths

4 Main Types of Battery Nickel Strip

Covering 1000+ ready-made molds, we support any custom tabs, rolls, or battery layouts you need.

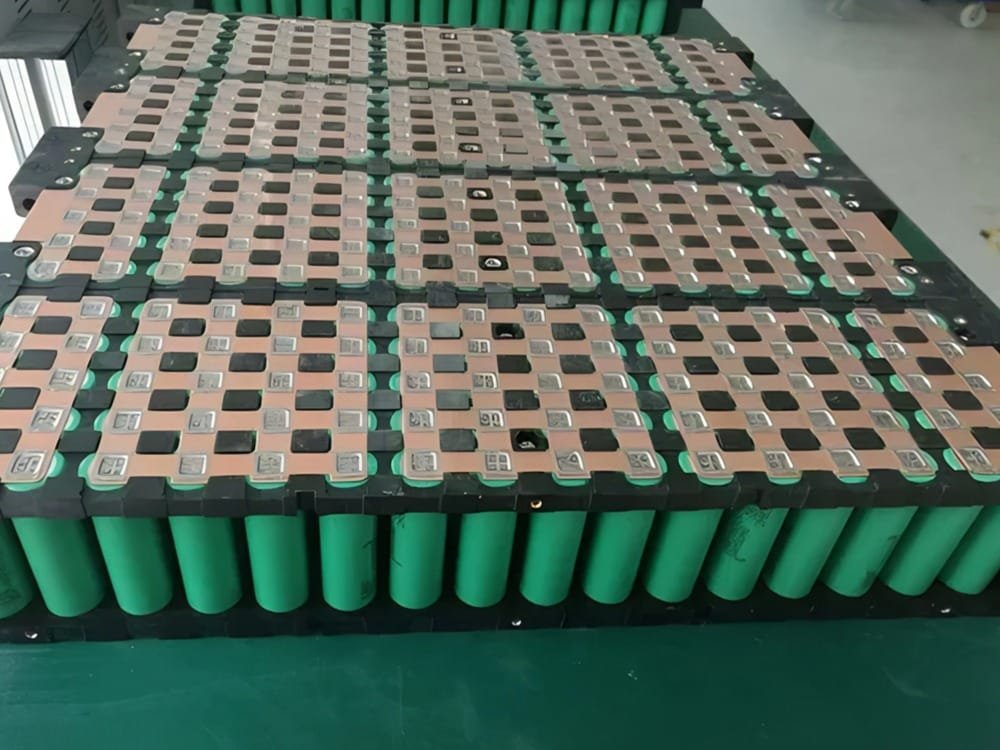

Stamped Nickel Tabs for Battery Packs

- Thickness: 0.10–0.50 mm

- Purity: ≥99.96% nickel

- Cell Fit: 18650 / 21700

- Tolerance: ±0.1 mm holes

Custom Shaped Nickel

Connectors

- Thickness: 0.10–0.50 mm

- Material: Nickel or composite

- Precision: ±0.05 mm

- Structure: Multi-bend design

Nickel Strip Roll for

Spot Welding

- Thickness: 0.10–0.50 mm

- Size: 6–12 mm wide

- Conductivity: ≤0.015 Ω·mm²/m

- Tensile Strength: ≥400 MPa

Slotted Nickel Strip for

18650 Pack

- Thickness: 0.10–0.50 mm

- Slot Pitch: 18.5 mm

- Welding: Laser / spot compatible

- Slot Tolerance: ±0.05 mm

6 Typical Uses of Our Nickel Strips

Our nickel strips are engineered for reliable performance across various battery applications. From e-mobility to energy storage, they ensure strong conductivity, stable welding, and long-term durability.

Our 4 Manufacturing Advantages

Over 99.96% purity, ±0.05 mm tolerance, RoHS & XRF certified – built for 20A+ discharge and high-speed automation.

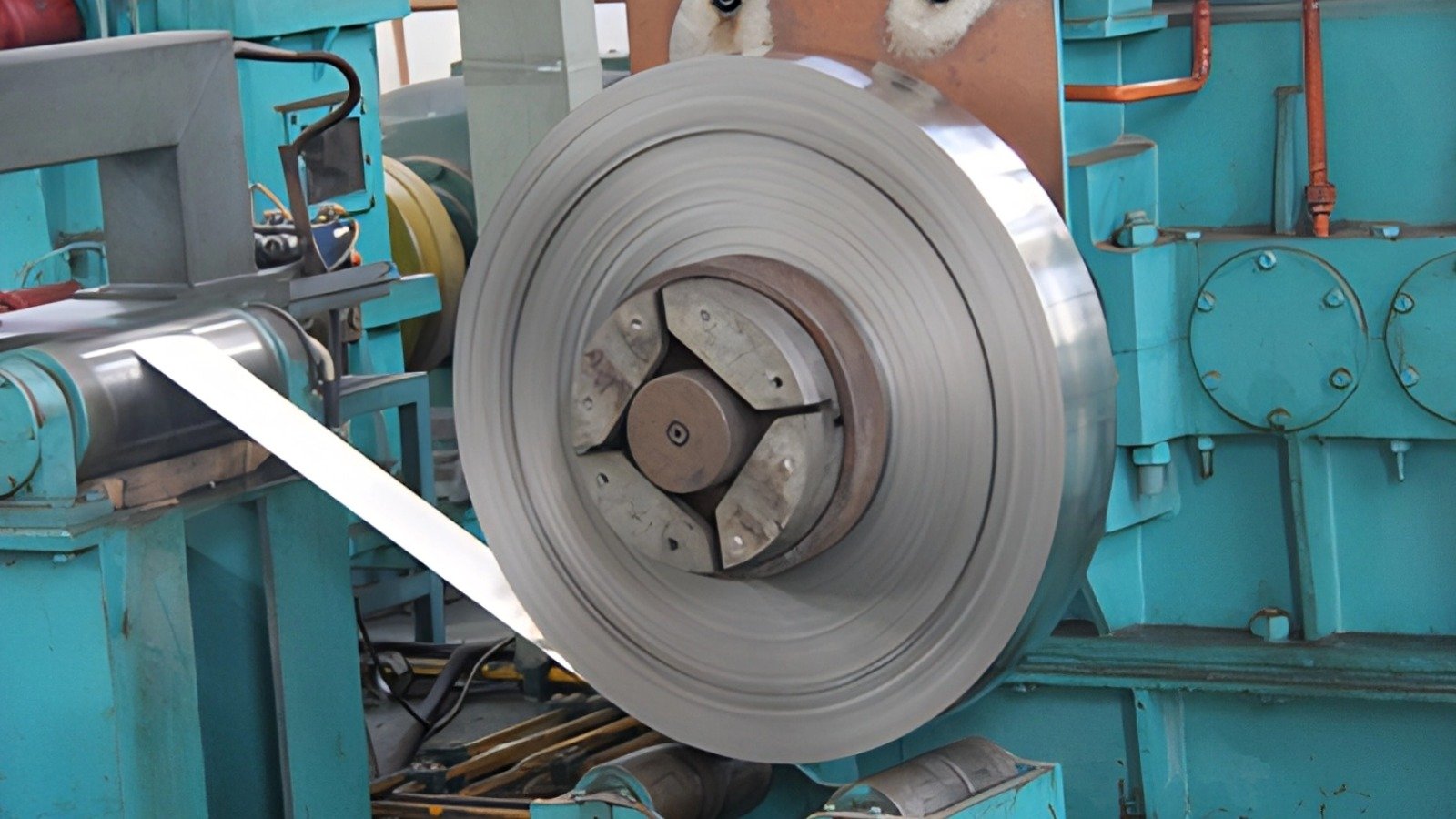

A. In-House Mold Fabrication

Equipped with 10+ Haitian injection machines and 200+ precision molds for battery parts. Mold prototyping in 3 days, supporting rapid tooling for custom cell housings and insulators.

C. Certification Wall

Over 20 certifications including RoHS, REACH, MSDS, ISO9001, ready for export to Europe, USA, Japan, Brazil. Ensures full compliance

for procurement audits.

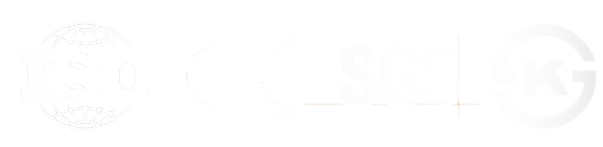

B. Raw Nickel Strip Processing

In-house slitting line supports 0.1–0.3 mm thickness, max width 80 mm, with annual capacity over 1,500 tons, ensuring stable supply for EV and energy storage clients.

D. Precision Cutting & Stamping

12+ high-speed cutting lines, delivering 2M+ custom nickel pieces daily. Supports tabs, slots, punch holes with micron-level precision for high-consistency welding performance.

Get Support Anytime You Need

Get your quote within 24 hours, backed by 1-on-1 engineering and sales support. From technical review to final delivery, we ensure fast response and seamless follow-up.

About AnnPower

Ann Power Technology Co., Ltd. is a leading supplier of lithium-ion battery components, integrating design, development, and manufacturing under one roof. Backed by over 10 years of expertise, our engineering, production, and sales teams have jointly developed more than 1,000 product types, including battery cases, holders, nickel strips, BMS, and chargers.

Our products are widely used in e-bikes, electric motorcycles, EVs, energy storage systems, power tools, and medical devices. We serve over 700 domestic battery manufacturers and export to countries including the USA, Germany, France, Spain, Switzerland, India, Korea, and Japan.

Our Delivery Capability

Our factory runs over 12 high-speed slitting and laser cutting lines, capable of processing more than 100,000 nickel components per day. With stable production schedules and flexible capacity, we ensure consistent output to match your dynamic supply chain needs.

From urgent custom orders to long-term programs, our team responds within 24 hours and guarantees on-time delivery at a 98.7% rate. You can count on our production strength to support your project from prototyping to mass production.

Our 6-Stage Quality Assurance Process

Covering 100% of incoming raw materials and 3 critical weldability tests per batch.

01 Rolling &

Thickness Control

Rolled multiple times to reach precise thickness such as 0.15mm ±0.01mm, ensuring uniformity across 100% of output.

02 Annealing &

Softening

Annealed under inert gas to achieve >20% elongation and enhanced welding compatibility for high-speed assembly.

03 Surface Cleaning & Treatment

Oil-free, oxide-free finish achieved via acid washing and polishing; 100% surface pass under ultrasonic weld test.

04 Slitting & Precision Punching

Cut to ±0.1mm accuracy, with slot/hole consistency over 95% alignment rate for automated tab applications.

05 Electrical & Mechanical Testing

Resistance range maintained within ±2% tolerance, tensile strength tested at >300 MPa to ensure structural stability.

06 Final QC & Protective Packaging

Each roll vacuum-packed with desiccant; 100% inspected for defects, oxidation, and dimensional deviations before shipment.

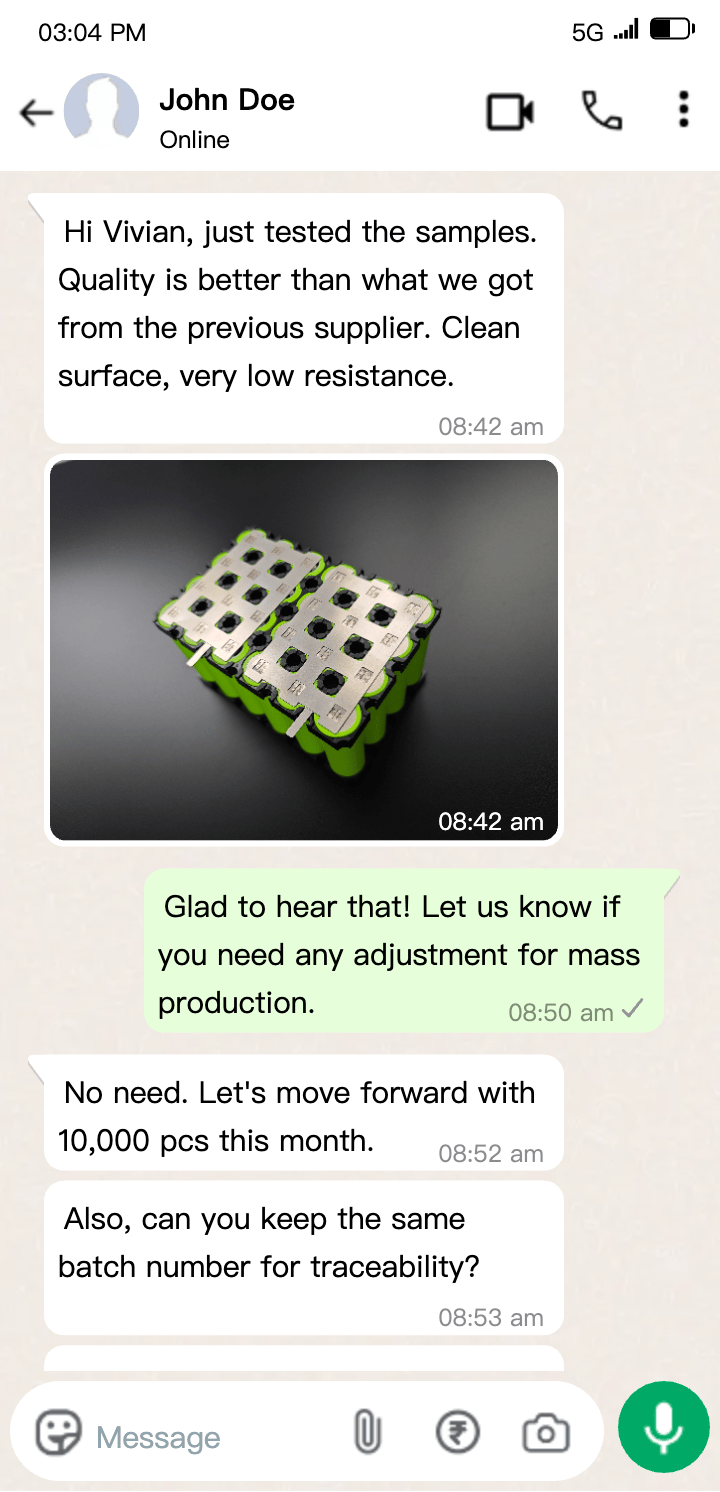

Custom Nickel Strips in 5 Simple Steps

From design to delivery, we provide full custom nickel strip solutions in 5 precise steps — fast, accurate, and mold-ready.

- Step 1: We confirm your nickel strip size, shape, and punching drawings.

- Step 2: Choose from 100+ molds or customize new tooling as needed.

- Step 3: Nickel rolls are slit and punched according to your exact specs.

- Step 4: We send custom samples for your testing and confirmation.

- Step 5: Start bulk production with stable lead time and secure packaging.

Hi, I’m Vivian — founder of this team.

With over 10 years in the battery materials industry, I help buyers like you get fast quotes, tailored solutions, and flawless production support. Let’s make sourcing simple and stress-free.

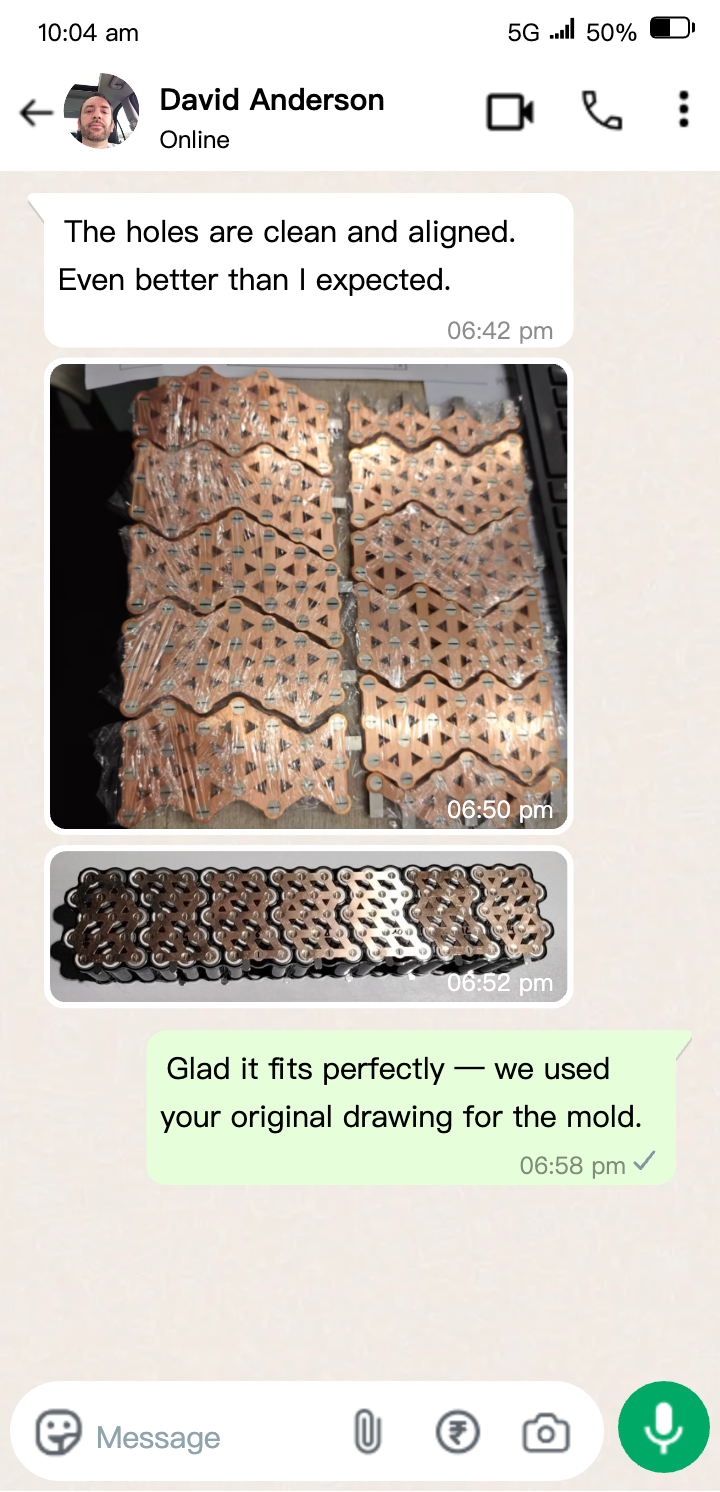

What Our Customers Say on WhatsApp

All reviews below come directly from real WhatsApp conversations with our global battery nickel strip buyers.

Welcoming Our Business Partner

It was a pleasure to welcome our business partner for an in-depth factory tour and technical discussion. Looking forward to more great cooperation!

30M+ Battery Tabs Delivered

100+ Tooling Dies for Nickel Strip Customization

10+ Years Serving B2B Battery Projects

90% of First-Time Clients Recommend Us

Common Questions

Quick Buyer Q&A

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Yes. We support custom width (2–50 mm), thickness (0.1–0.3 mm), and punching based on drawings. Over 100 molds available for flexible production.

Absolutely. All our strips are RoHS-compliant, and we provide material certificates (XRF/COA) with every shipment.

Typically 7–10 working days after confirmation. For urgent orders, 3-day express production is available.

We apply a 6-step QC process, from raw material inspection to final packaging. Reports include thickness, resistance, and tensile test data. requirements of different construction projects.

Certifications & Quality Assurance

All our nickel strips are RoHS & REACH compliant, with XRF reports, MSDS, and ISO certifications available. Each batch can be traced and verified for quality and safety.

Request a Custom Quote

Share your battery type, tab size, or resistance requirements.

Our engineering team will analyze your specs and provide a tailored nickel strip solution.

You’ll receive detailed pricing and production lead time within 24 hours.Whether it’s a standard size or a custom die-cut format, we’re ready to support you from prototype to bulk orders.

Fast feedback, expert advice, and competitive factory pricing—all in one step.

Email:vivian@annbattery.com

Annpower Tech

Upload Your Drawing

Send your sketch or file. We’ll provide optimized design feedback and a complete packaging plan in 1 day.